Our Precision Solutions

Explore our range of ultra-precision optical processing services. Tailored solutions for seamless production in the semiconductor industry.

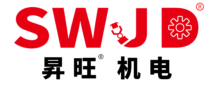

Ion beam polishing machine case

The new generation of ion beam polishing machine can process subnanometer precision, and can realize the surface shape RMS<1nm ultra-high precision machining size of the workpiece, with the processing ability of plane, spherical, aspherical, off-axis surface, free-form surface and other optical parts.

The equipment is composed of vacuum system, motion system, ion source system, workpiece system, electrical control system and software system.

With plane, spherical, aspherical, off-axis surface, free surface and other optical parts processing ability. The processing materials are quartz, microcrystal, ULE, sapphire, monocrystalline silicon, silicon carbide, etc.

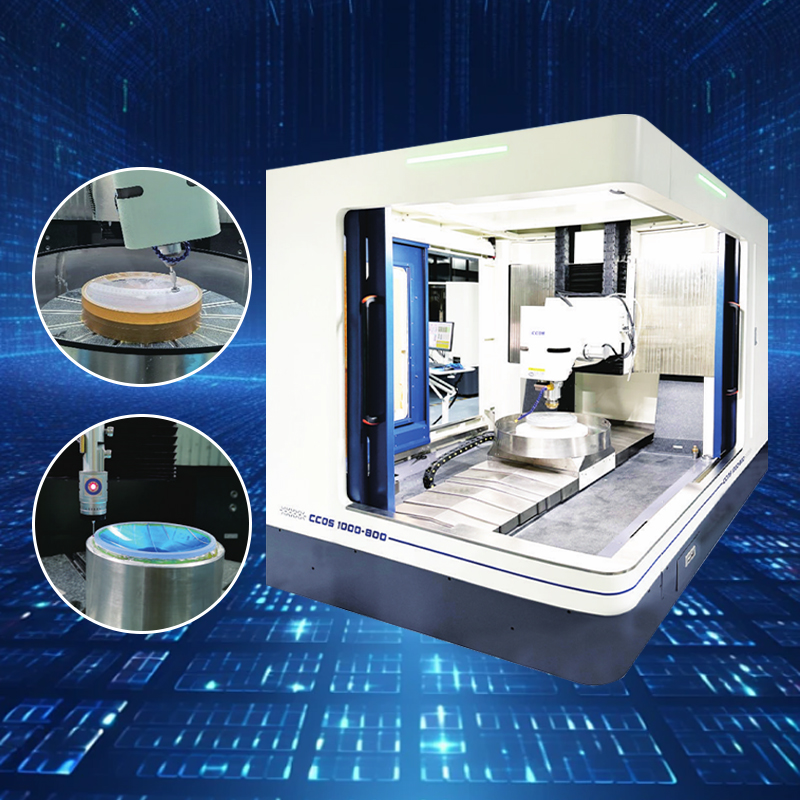

Magnetorheological polishing machine

Magnetorheological polishing machine adopts high-precision marble bed, with 6-axis 6-linkage function, workpiece intelligent positioning, fluid flexible polishing, to achieve high efficiency and high-quality precision optical processing, processing nano precision, can achieve surface RMS<3nm high-precision processing; It has the processing ability of planar, spherical, aspherical and other optical parts, and has the advantages of high stiffness, high precision, high dynamic characteristics, powerful function, convenient operation and intelligent. Processing materials quartz, microcrystal, ULE, K9, sapphire, monocrystalline silicon, silicon carbide, zinc sulfide, etc.

CNC small grinding head polishing machine

Precision optical CNC small grinding head polishing machine adopts deterministic polishing, to achieve high efficiency and high quality precision optical processing, with six axes and six linkage, three types of polishing head, workpiece intelligent positioning, can process plane, spherical, aspherical, off-axis, cylindrical, free surface, etc. The processing materials include quartz, microcrystal, ULE, K9, sapphire, monocrystalline silicon, silicon carbide, zinc sulfide, etc.

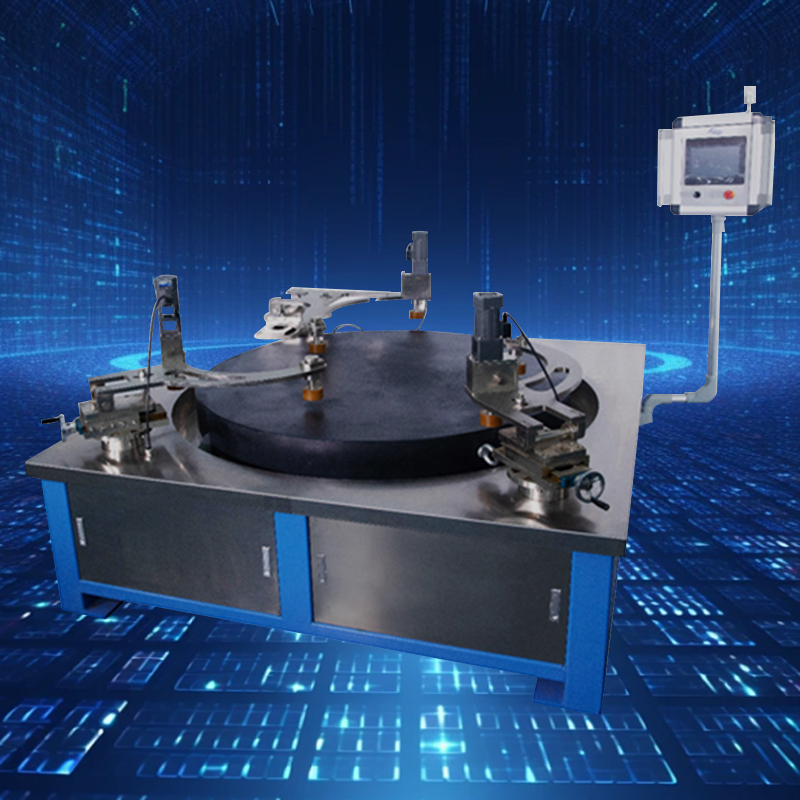

Full Aperture Intelligent Continue Polisher

Provide various specifications of the continue polisher, It has the

function of automatic monitoring and control of all process parameters

such as rotate speed, eccentricity and unloading of correction plate.Full caliber intelligent continue polisher with high-flatness marble, high-precision turntable bearing,servo motor, constant torque output,PLC + HMI.Integrated process parameter monitoring, surface online monitoring and real-time acquisition of process

parameters through automation program..Polishing glue, automatic liquid injection system, automatic slotting and other technical support for the

whole process chain of continue polishing. We can provide samples for trial production.The attachment device for customization

Pneumatic four-axis grinding and polishing machine

Provide a variety of specifications of polishing and grinding discs, which can be used for the grinding and polishing of flat and spherical surfaces of various brittle materials such as optical glass, quartz,crystals, etc.The machine tool itself adopts frequency conversion speed regulation, and its spindle and pendulum shaft can be controlled separately. High torque, no vibration and low noise, which can meet the requirements of

a variety of optical processes It can be individually adjusted according to the needs of the machined parts.

Multi-Function Desktop Robot Polisher

The Computer Control Optic Surfacing Polisher Basing on mini industrial robot,with less space and more

flexibility. The surface error is figured by the polishing spindle tool, using for optical plane, spherical and

aspheric surface.

The fitting polishing tool technology basing on the polishing force controller was developed to get the

controllable Influence Function and finish the precision optical surface. And High Mark will provide full

process solutions from micron to nanometre with the innovative process technology and software.

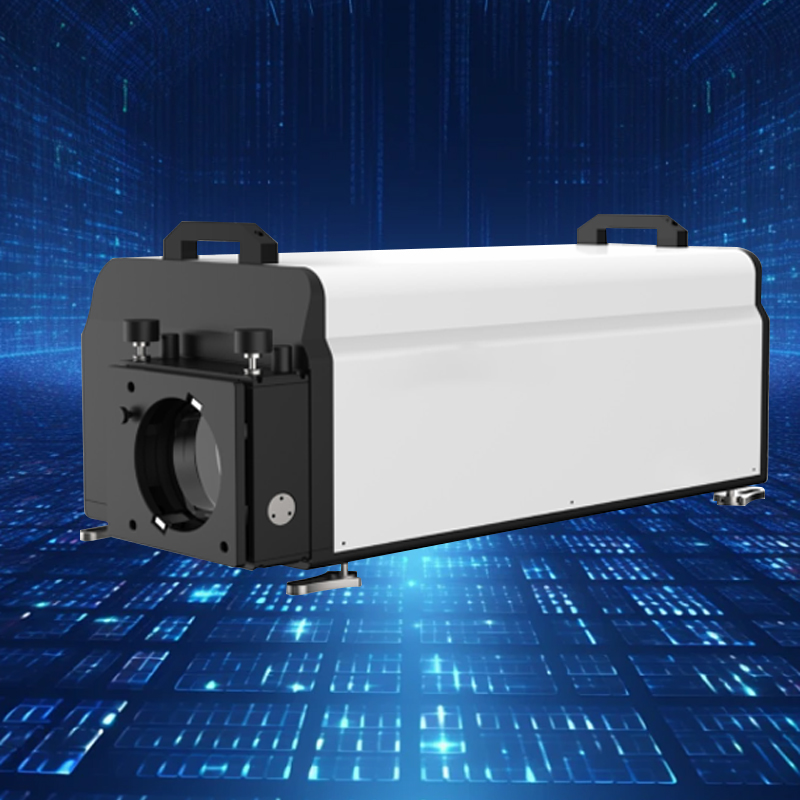

4-inch Laser Interferometer

Base on phase-shifting technique, the laser interferometer, widely used in the high-precision measurement of planar and spherical optical components,characterizes the three -dimensional topography of the measured surface with a precision of 0.06 μm (Peak-to-valley) or higher. Precisely measure the transmitted and reflected wavefronts of optical components with diameters up to 4 inches. The measurement precision and repeatability are comparable to American Zygo and 4D interferometers. Customized instruments can be developed according to customer requirements.

Multi-wavelength Laser Planar Interferometer

Based on the principle of Fizeau interference and mechanical phase shifting and equipped with the self-developed super-achromatic beam expanding and imaging system, the interferometer supports the plug and play of laser source with the working wavelength in the range of 600 – 1600 nm.When changing laser source with another wavelength, no adjustment is needed.The interferometer can be equipped with self-developed absolute test accessories to obtain the absolute surface error of a surface with an accuracy better than λ/40.

Large-aperture Laser Interferometer

Base on phase-shifting technique, the laser interferometer,widely used in the high-precision measurement of planar and spherical optical components, characterizes the three-dimensional topography of the measured surface with a precision of 0.06 μm (Peak-to-valley) or higher .Precisely measure the transmitted and reflected wavefronts of optical components with diameters up to 32 inches.The measurement precision and repeatability are comparable to American Zygo and 4D interferometers. Customized instruments can be developed according to customer requirements.